How to Set a Torque Wrench in Inch Pounds: A Complete Guide

Let’s say you need to set a bolt in at a specific amount of tightness but applying a torque higher than the set amount could damage the bolt. Unfortunately, the amount of recommended torque for the equipment is valued in Newton meters, so you might be asking yourself how to set a torque wrench in inch pounds.

Knowing how to properly set a torque wrench every time you use it is crucial for accuracy. On top of that, you should have an understanding of the various torque units and how to convert from one unit into another.

To that end, we will do an in-depth discussion on how you can set a torque wrench in different units, as well as the interconversion between these units.

What Is a Torque Wrench?

A torque wrench is sophisticated mechanical equipment that can come in handy every time you need a precise amount of torque applied.

Modern machinery has nuts and bolts that can be tightened only up to a certain amount, and if they’re put under a higher amount of pressure than the set torque limit, the bolt or the machinery itself can get damaged.

People might argue that if you have the superior instincts of a mechanic, then you can precisely tell when the torque limit has been reached, so even a breaker bar can substitute for a torque wrench. This couldn’t be more wrong, as even the slightest error could end up damaging your expensive equipment.

This is where a torque wrench comes to the rescue. While there are many types of torque wrenches in the market, click-type torque wrenches, which are the most common, can help the user know when the set torque amount has been applied by producing a clicking sound. Once you hear the clicking sound, you should immediately stop applying more force.

How to Set a Torque Wrench in Inch Pounds as the Unit

Obtain the Recommended Torque Value

You will have to set up a torque wrench every time you use it. To do that, you will have to first find out the amount of torque that is required for the task you’re going to perform. Take note of the unit of the torque as well, because we might need to convert it later down the line.

Once you have the value and unit of the torque, take hold of your torque wrench. Ideally, you should have a dual-range torque wrench, which has markings in foot-pounds and Newton meters. This makes the setup much easier.

If the required torque is in any one of these two units, opt for that scale when setting up the torque wrench. If the units of the required torque are in inch-pounds, then you will have to do some unit conversions, which we will discuss in a bit.

Coarse Adjustment

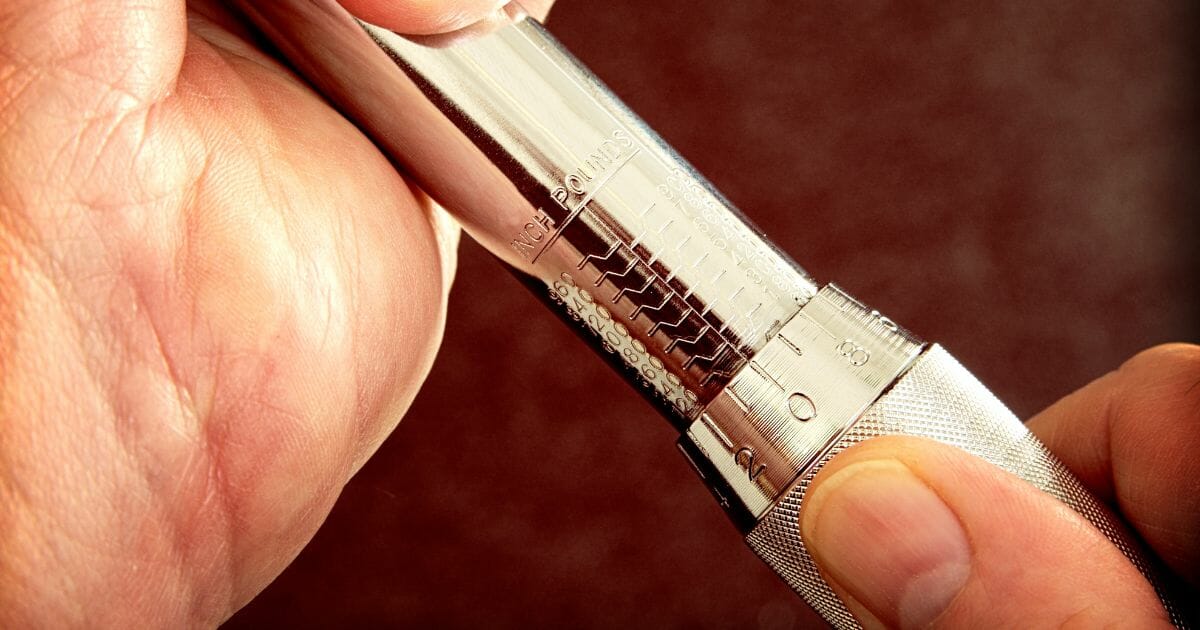

Once you have the wrench in your hand, you’ll notice that there are two different scales on it. One of the scales has higher readings, while the other has much smaller increments.

The larger and vertical scale, which is present on the main body of the wrench, is for coarse adjustment. Adjusting this will be our first step.

Try to find the locking mechanism, which can either be on the handle of the wrench or the bottom, depending on what kind of wrench you have. Once located, rotate it to unlock the wrench.

Next, use the knurled wrench handle to roughly set the main scale close to the value of maximum torque for the component that you obtained. For most wrenches, rotating clockwise increases the torque and vice versa. When setting up the main scale, always round down the torque value to the smaller increment. The second scale will be used to lock in the exact value of torque.

Finer Adjustment

Because the larger scale only makes increments of 15, 50, 100, or anything in between these values, depending on which wrench you have, we need the smaller scale to input the exact torque value for accuracy.

After you have roughly set the larger scale, make sure that the smaller scale corresponds to 0 before you start setting it.

Once again, we will have to rotate the knurled handle, but this time, our focus should be on the horizontal scale instead of the one on the main body of the wrench. Slowly rotate the knurled handle until you reach the desired marking.

In order to check if you have set the torque value correctly, just add the numbers on both scales. From the larger scale, take the number that you rounded down to. To that number, add the integer on which you set the smaller scale. The sum should add up to the desired amount you want to output for your task.

Unit Conversion

In case your wrench doesn’t have the required units, you will need to convert between the different units of torque. Let’s find out how you can do that.

Feet-lbs to Inch-lbs

Most wrenches have feet-lbs reading on them. Even if it doesn’t have an inch-lbs scale, converting from feet-lbs to inch-lbs is fairly straightforward.

To convert feet-lbs to inch-lbs, just multiply the number by 12.

For instance, 10 foot pounds = 120 inch pounds.

If you divide the inch-lbs value by 12, the unit will change to feet-lbs.

Newton Meter to Inch-lbs

The Newton meter is the Standard International (SI) unit of torque, so most wrenches will have this reading. Converting from Nm to inch-lbs is slightly more complicated, so you might need a calculator.

To convert Nm to inch-lbs, multiply the value by 8.85.

For instance, 10 Newton meters = 88.5 inch pounds.

If you divide the inch-lbs value by 8.85, the unit will change to Newton meter.

Feet-lbs to Newton Meter

Converting from a feet-lbs torque value to Newton meter is also quite easy, but you might need a calculator for this.

To convert feet-lbs to Nm, multiply the torque by 1.356.

For instance, 10 Feet Pounds = 13.56 Newton meters.

If you divide torque in Nm by 1.356, the unit will change to feet-lbs.

What Is the Best Type of Torque Wrench?

If you’re sick of constantly having to convert your units, then a digital torque wrench is the best for you.

Apart from the increased accuracy, these have an in-built digital display that you can use to set the torque in the unit you require, just with the press of a button.

If you don’t want a torque setting, then a digital wrench has an angle setting, which you can use to rotate a bolt at a specific angle.

When the torque limit is reached, the digital wrenches emit a loud alarm to indicate that you should stop applying any more pressure.

Conclusion

Now that you know how to set a torque wrench in inch pounds, you can confidently tackle any scenario. As a general rule of thumb, always opt for a wrench that has more than one unit of torque on it. You can even opt for a digital torque wrench, which might need batteries to work, but they make unit conversions a thing of the past.

Before buying a torque wrench, always pick the correct size and length of the handle, specific to the applications you’ll use it in. Also make sure that when you’re storing the wrench, it’s set at the lowest torque ranges. This puts minimum pressure on the spring present inside the handle and will help the torque wrench stay calibrated for a longer period.